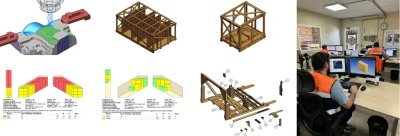

Industrial packaging design has evolved significantly in recent years, especially in the context of the transport of special goods. This type of cargo, which includes large tonnage or highly sensitive equipment (physical, thermal, environmental, etc.), presents unique challenges. Transporting these products over long distances, such as from one continent to another by sea, requires specialised packaging solutions adapted to the characteristics of each piece of equipment or machine. In this regard, the use of advanced technologies such as 3D design has become a key tool to optimise both cargo safety and operational and environmental costs.

One of the main challenges in the design of packaging for the transport of special goods is to ensure adequate protection of the equipment during the entire logistics process (lashing, transport, etc.). Heavy or extremely fragile loads require a detailed analysis of the conditions they will face during transit. For example, vibrations, temperature changes, humidity or even the rocking of the ship at sea can affect the integrity of the cargo if it is not properly packed. This is where 3D packaging design plays a key role. This technology allows you to create accurate simulations of the packaging, anticipating potential problems and adjusting materials and structure as necessary.

Cost optimisation with good packaging design

Good industrial packaging design not only ensures the safety of the load, but can also optimise costs. By creating three-dimensional models, it is possible to analyse the weight and volume of the packaging, thus reducing unnecessary excess materials. This not only reduces transport costs, but also contributes to a lower environmental impact by reducing the amount of waste generated and CO2 emissions from transport. 3D design facilitates the creation of lighter but equally strong packaging, which represents both an economic and ecological advantage.

At Embalex, we are specialists in industrial packaging design, especially in complex projects involving special goods. We have a dedicated engineering and R&D team that works exclusively on creating customised packaging solutions. Our process begins with the creation of 2D CAD/CAM drawings, which allows us to have an accurate representation of the dimensions and characteristics of the packaging. We then move on to the 3D design and optimisation process, where we evaluate the behaviour of the packaging in different conditions and adjust details such as the type of materials or structural reinforcements.

Además, ofrecemos la creación de prototipos a escala para validar las soluciones propuestas, asegurando que el diseño final cumpla con todos los requisitos técnicos y operativos. También realizamos auditorías de embalaje para garantizar que se cumplan las normativas y estándares de protección más rigurosos. Proporcionamos informes periciales detallados, así como información técnica y manuales de ensamblaje y desensamblaje para asegurar que todo el proceso de embalaje y desembalaje sea eficiente y seguro.

En conclusión, el diseño de embalaje para transporte de mercancías especiales es una tarea compleja que requiere precisión, experiencia y tecnología avanzada. La integración de herramientas como el diseño 3D permite crear soluciones óptimas que no solo protegen la carga durante su transporte, sino que también ofrecen ventajas económicas y ambientales. En Embalex, una empresa nacida en Barcelona con más de 106 años de experiencia, somos punteros en soluciones innovadoras y personalizadas para garantizar el éxito de cada proyecto.