1. Detailed analysis of product requirements and characteristics: The first step in the design of large packaging is to carry out a thorough analysis of the product's specific requirements and characteristics. This involves assessing the exact dimensions, weight, centre of gravity, fragility, critical support points and any special handling and transport requirements. A detailed knowledge of these variables will allow a custom packaging to be designed perfectly suited to the needs of the product.

2. Selection of strong and durable materials: The choice of suitable materials is essential in the design of large packaging. Strong, durable materials must be selected that can withstand the weight and protect the contents during transport. Some common options include high-strength corrugated cardboard, plywood, high-density plastics such as polyethylene or polypropylene, and metal structures such as aluminium or steel. The choice of material must be based on product characteristics, strength requirements, necessary rigidity and ability to withstand handling and environmental conditions.

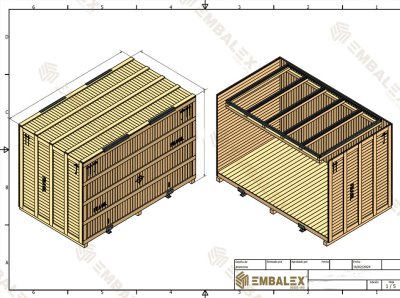

3. Strong structural design and additional reinforcements: The structural design of large packaging must be strong and robust to ensure adequate protection of the product during transport. Additional reinforcements, such as reinforcement beams, profiles or internal structures, must be considered to increase the strength and stability of the packaging. These reinforcements can be made of materials such as double-wall corrugated cardboard, additional plywood panels or steel profiles. The structural design must take into account load distribution, critical support points and compressive stresses to avoid deformation and damage during transport.

4. Cushioning and restraint systems: The design of large packaging must incorporate cushioning and restraint systems to protect the product during transport, especially against sudden movements and vibrations. Cushioning materials such as high density polyethylene or polyurethane foams, bubble sheets and air cushions can be used to protect the product from shock and vibration. In addition, restraint systems such as lashing straps, polypropylene bands or tie-down straps must be used to ensure that the product remains in place and to prevent unwanted movement.

5. Logistical and handling considerations: When designing large packaging, it is important to take logistical and handling considerations into account. This involves assessing the space available for storage and loading into trucks or containers. In addition, handling elements such as handles, wheels or lifting mechanisms should be incorporated to facilitate handling and movement of the packaging. Access openings or doors may also be included to allow inspection and access to the product during transport, if necessary.

6. Design testing and validation: A crucial stage in the design of large packaging is design testing and validation. Endurance tests, vibration tests and impact tests must be carried out to assess the effectiveness of the packaging in protecting the product. These tests help identify possible improvements and to make necessary adjustments to ensure maximum safety during transport.

Conclusion: The custom design of large packaging requires a detailed and technical approach. Through analysis of product requirements and characteristics, selection of robust materials, sound structural design, appropriate cushioning and restraint systems, logistical considerations and validation testing, efficient and safe packaging can be achieved. Packaging specifically designed for large products ensures the protection and integrity of the product during the entire transport process.