What standards exist for the packaging and transport of vehicle batteries?

As they are lithium batteries, a hazardous material, the transport and packaging of electric vehicle (EV) batteries is regulated by a series of international standards and guidelines, whose objective is to guarantee the safe handling and transport of these batteries. These regulations cover various aspects of batteries, such as their design, construction and performance, as well as their packaging and labeling requirements.

UN regulations

One of the key regulations for the transport of electric vehicle batteries is the United Nations (UN) Recommendations on the Transport of Dangerous Goods, commonly known as the UN Model Regulations. This document establishes the requirements for the classification, packaging, marking, labeling and documentation of dangerous goods, including lithium-ion batteries.

Under the UN Model Regulations, lithium-ion batteries are classified as Class 9 dangerous goods, which are defined as "substances and articles that are not covered by other classes and are presented in a non-hazardous form." This classification reflects the fact that lithium-ion batteries do not pose a significant risk of fire or explosion under normal conditions, but can become dangerous if damaged or subjected to extreme temperatures or other adverse conditions.

ICAO International Guidelines

In addition to the UN Model Regulations, there are other international standards and guidelines related to the transport of electric vehicle batteries. One of these is the International Civil Aviation Organization (ICAO) Technical Instructions for the Safe Air Transport of Dangerous Goods, which establish the requirements for the air transport of dangerous goods, including lithium-ion batteries.

IMDG regulations for the transport of lithium batteries

Another important standard for the transport of electric vehicle batteries is the International Maritime Dangerous Goods (IMDG) Code, which is the main international standard for the safe transport of dangerous goods by sea.

This code establishes the requirements for the classification, packaging, marking, labeling, and documentation of dangerous goods, including lithium-ion batteries.

In addition to this regulation, there are also various standards and guidelines related to the packaging of batteries for electric vehicles. One of the key standards for the packaging of lithium-ion batteries is the International Electrotechnical Commission (IEC) 62133, which regulates the safety requirements for secondary cells and batteries that contain alkaline or non-acid electrolytes. This standard establishes the design, construction and performance requirements for lithium-ion batteries, as well as the testing and certification requirements for these batteries.

ISO/IEC 17025 Regulation for lithium battery test laboratories

Lastly, for the packaging of electric vehicle batteries, it is ISO/IEC 17025, which establishes the general competence requirements for testing and calibration laboratories. This standard establishes the requirements for personnel, facilities, equipment and processes used by testing and calibration laboratories, as well as the requirements for the management and documentation of these laboratories.

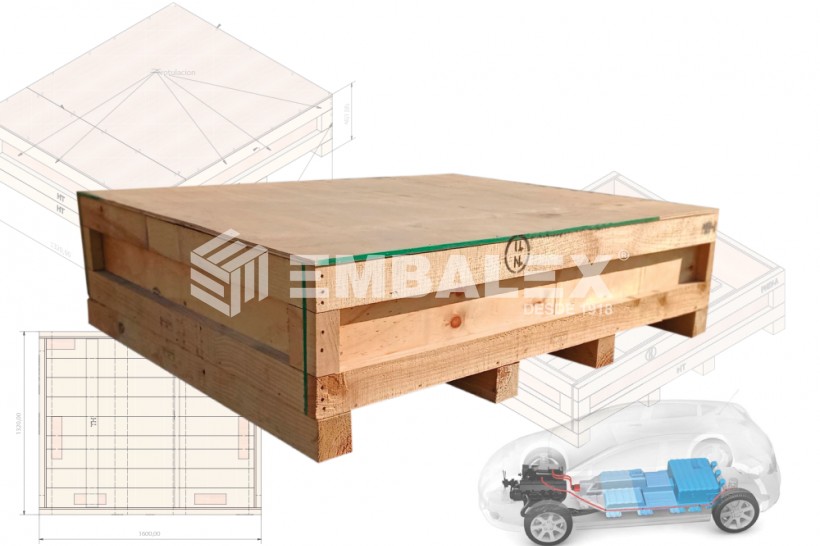

Aspects that an industrial packaging company must take into account when shipping electric car batteries

In addition to these standards, there are also various guidelines and good practices related to the transport and packaging of electric vehicle batteries that an industrial packaging company must follow. These guidelines and best practices have been developed by industry organizations and trade associations, and are designed to guide manufacturers, shippers, and other interested parties on the safe handling and transportation of electric vehicle batteries.

In general, the regulations and standards for the transport and packaging of electric vehicle batteries are designed to ensure the safe handling and transport of these batteries, and to prevent accidents that could be caused by damaged or malfunctioning batteries. By following these regulations and standards when designing packaging for batteries, we can ensure maximum safety and avoid shipping problems.