Big Data technology consists of the ability to collect large amounts of data that can be exploited to optimize processes. In this way, the information extracted from these data allows more accurate predictions to be made about industrial packaging demands, as well as taking into account the influence of external factors that could not previously be taken into account precisely because of the lack of data on them. By better predicting demand, the quantities of safety and storage stocks required are reduced, which affects the efficiency of logistics companies in carrying out their business.

To be able to exploit this huge amount of data to the full, it is essential to use artificial intelligence, which will use it to provide more effective solutions throughout the production chain. In the industrial packaging sector, where transport is so important, artificial intelligence allows for better route calculations, storage automation, etc., but also offers a personalized analysis of the goods to be packed, selecting the best industrial packaging according to the load.

The advance of artificial intelligence, together with connectivity technologies such as 5G, is allowing the development of more and more intelligent objects capable of connecting to each other. This is what is known as the internet of things and is revolutionizing the logistics sector by interconnecting goods, warehouses, means of transport, systems and companies, making logistics more reliable and efficient, and allowing continuous monitoring of the goods both during transport and during loading, unloading and storage, reporting any damage to the integrity of the packaging at the time.

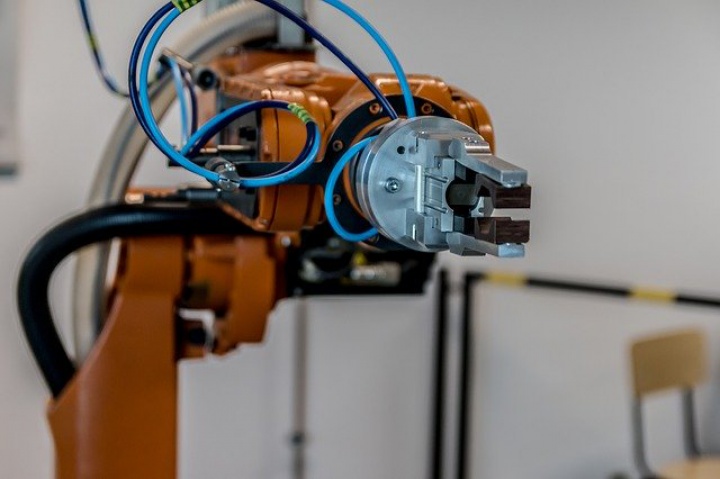

On the other hand, the progress of robotics is also having a strong impact on the logistics sector in general, and also on industrial packaging, where the automation of the different processes is revolutionizing the efficiency of packaging, storage and management of goods.

The adoption of all these technologies and others such as drones or autonomous vehicles, are making the tasks of industrial packaging and logistics more efficient, greatly expanding business opportunities and production and consumption models. However, it should not be forgotten that all these advances must also be accompanied by a parallel development of cybersecurity that guarantees the protection of personal, business and product data, as well as stricter compliance with legislation on network security.